Fleece Testing

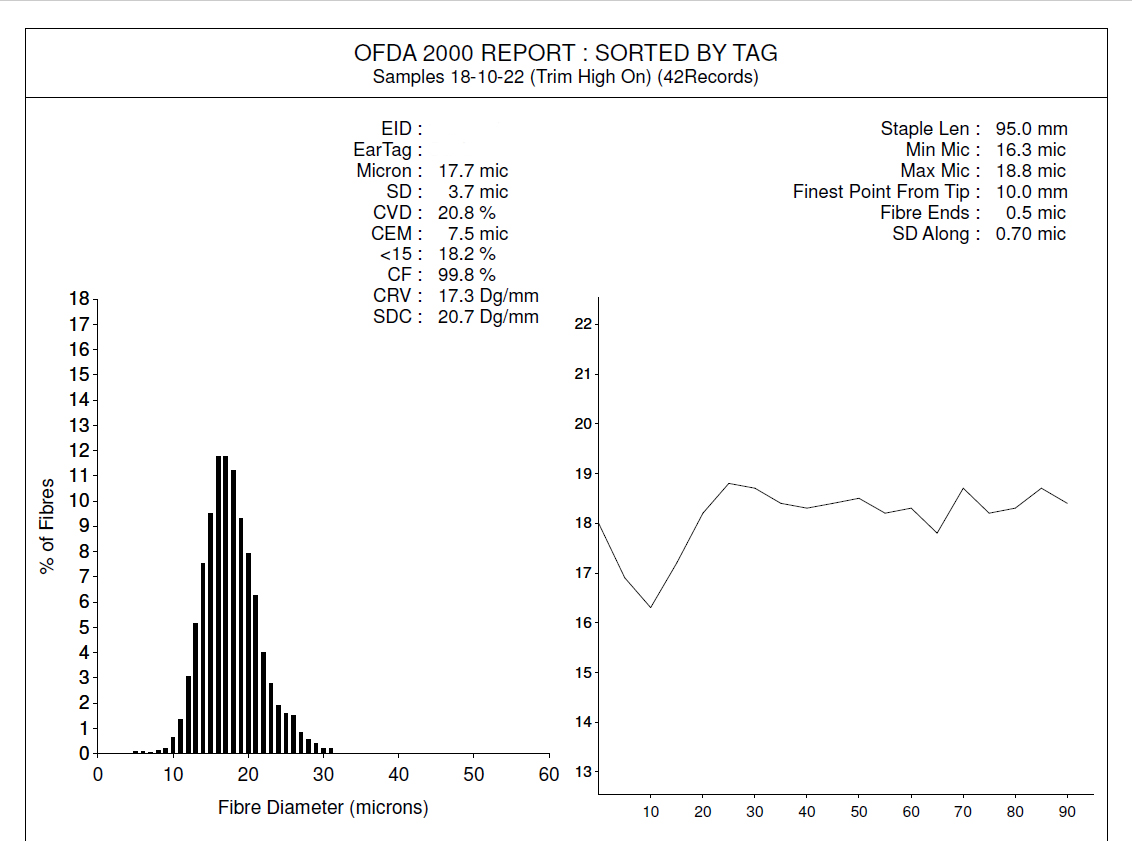

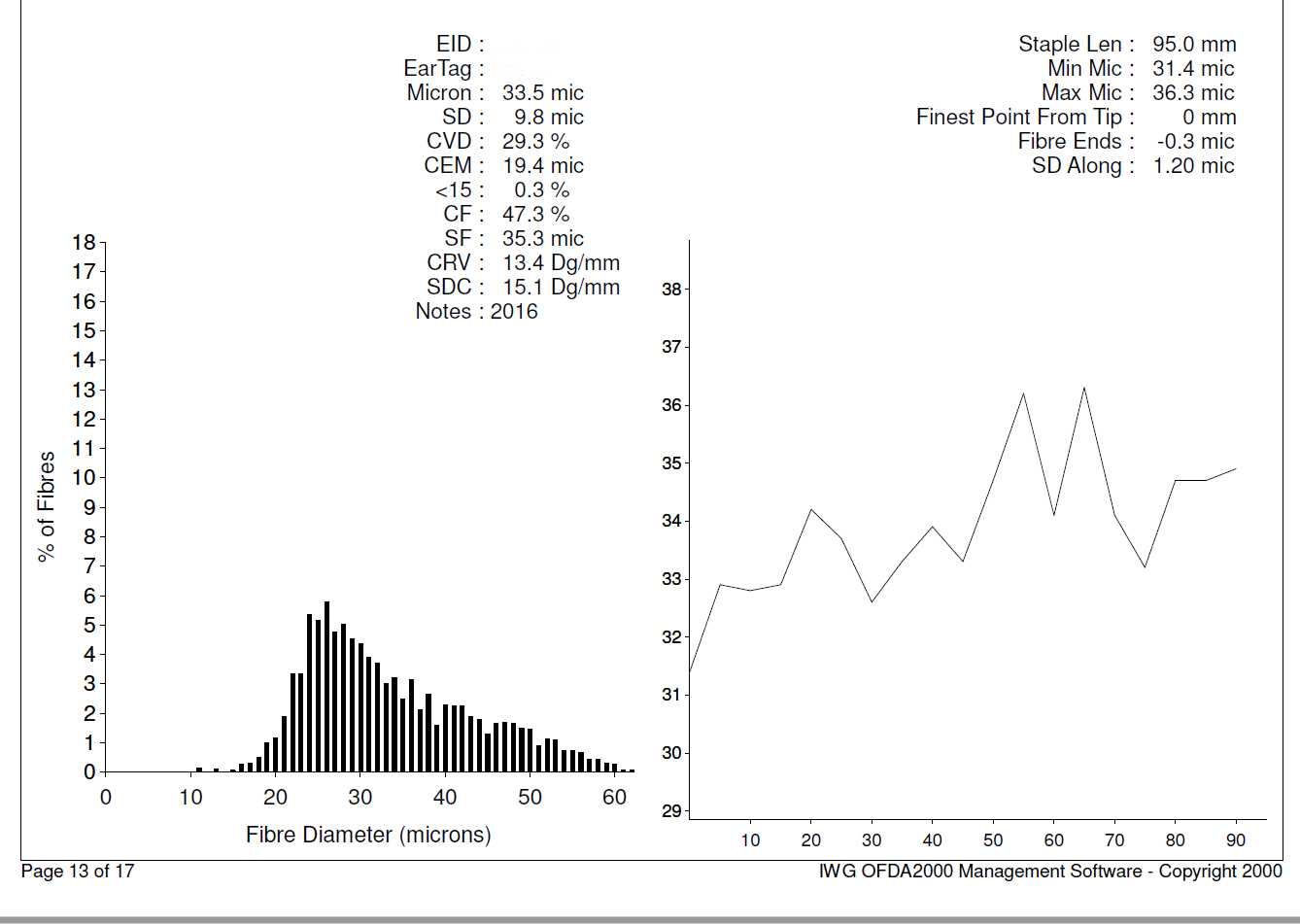

Histogram

Fleece testing is a tool used by many breeders to get an objective measurement of fleece traits, e.g. micron diameter, prevalence of coarse fibres, uniformity of micron etc.

It is important to keep records of each alpaca’s test results so that you can use this information in your breeding decisions.

Mid-side Sample

It is recommended to take fleece samples before shearing at the mid side of the alpaca. Samples can also be taken at shearing. Send to the same tester every year to get a trend in the herd. Fleece taken from the mid-side of an alpaca is representative of the average fleece results across the body, so it is the area of the animal that the sample should come from. Identify the mid-side approximately midway between the back bone and the belly and midway between the forequarter and the rump. Before sending away for testing shake out any seeds or dust from the sample. A graphical representation of the frequency of fibre diameters in the sample. The peak shows the Mean Fibre

Diameter, and the Standard Deviation is shown in the spread of the bottom of the graph.

Mean Fibre Diameter (MFD)

Commonly referred to as “micron”, is the overall average fibre diameter. Measured in micron (µm).

Standard Deviation (SD)

The standard deviation measures (in micron µm) how wide the spread is, of individual fibre diameters, around the mean (MFD). 66% of fibres fall within this range. SD is

expressed as a figure + or - the mean. For example a fleece with a mean micron measurement of 16 and an SD of 3.5 micron should be described as having an ‘SD of plus or

minus 3.5 microns about the mean’. Using this example, 66% of the fibres measured in the sample will have their fibre diameter fall between 12.5 microns and 19.5 microns

(subtract 3.5 from the mean of 16 to get the lowest figure and add 3.5 to 16 to get the highest figure). The lower the SD the more uniform and desirable the fleece is.

Coefficient of Variation (CV)

The coefficient of variation is the SD expressed as a percentage of the MFD. The SD is multiplied by 100 and divided by the MFD. MFD indicated at peak SD indicated

around the mean Diameter – length profile

- Diameter- length profile (from OFDA2000) graphically

indicates growing history since birth or the last

shearing

Comfort Factor (CF)

The comfort factor is the percentage of fibres under 30 micron. Length (Len) The staple length of the sample.

Curvature Fibre

Curvature is related to the crimp frequency of the fibre. It is measured in degrees per millimetre (Dg/mm) and is the amount of bend or curve over 1mm

AN EXAMPLE OF HISTOGRAMS - DESIRABLE AND UNDESIRABLE